What is High Pressure Processing (HPP)?

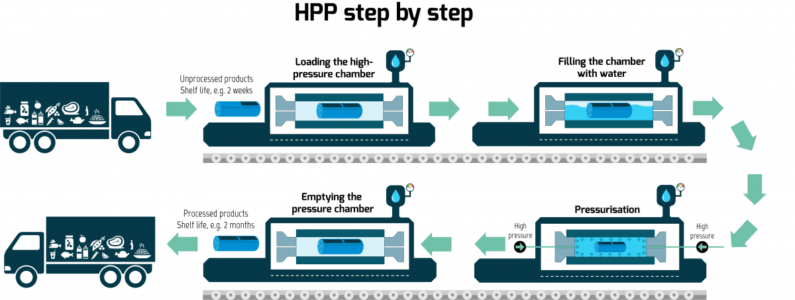

HPP is a cold pasteurization technique by which products, already sealed in its final package, are introduced into a HighPressure vessel and exposed to a ultrahigh isostatic pressure (300–600 MPa) transmitted by water.

- bacteria,

- viruses,

- yeasts,

- moulds

- parasites

HPP is a method of food sterilization using water to pressurize the product to between 4,000 to 6,000 Bar (equivalent 60,000 meters below sea level) to pasteurize products without additional heat. This ensures no loss of vitamins, flavors or texture of the product.

read more about HPP here

read more about HPP Technology here

read more about HPP Advantages here

read more about HPP Applications here