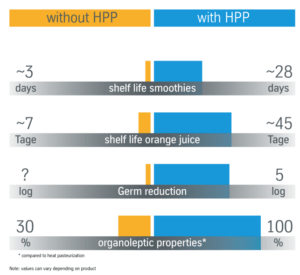

HPP technology (high pressure processing) is non-thermal and high-pressure process for food which is packed in the final packaging, in order to improve safety, reduce additives (such as salt or inert gas) and extend shelf life.

INTRODUCTION

The food industry aims to develop innovative products through new processing methods. They allow to create products that could not be produced before. One of the most successful achievements so far is High Pressure Processing called also High Pressure Pasteurization.

High Pressure Processing is a cold pasteurization technique. It consists of subjecting food, previously closed in a flexible and waterproof package, to high hydrostatic pressure (pressure transmitted through liquid/water) up to 600 MPa (6000 bar) and holding for several minutes. A similar pressure could exist in the ocean at a depth of 60 km – if such a deep crevice existed. At the bottom of the Marian Trench is a pressure of about 600 bars !!!

Although non-thermal high-pressure pasteurization of food products has been known since the 19th century, it was only in the 1990s that the first products were developed. Since 2000, the hpp technology have been successfully implemented in all branches of the food industry worldwide. High pressure processing is a natural, environmentally friendly process that preserves nutrients and helps to preserve fresh food features such as taste and color. It is a real alternative to traditional thermal and chemical treatments.

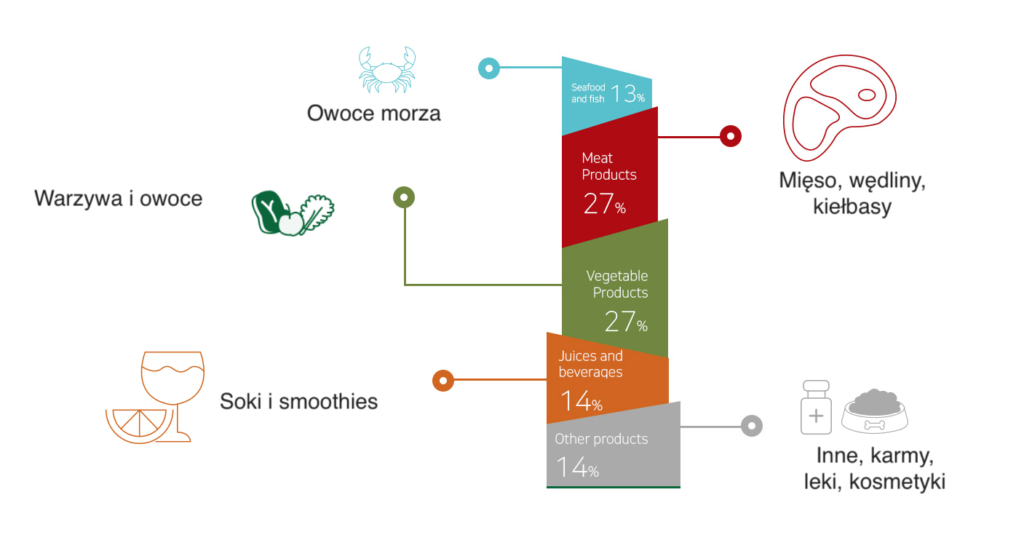

Statistical use of HPP in various food products, globally in 2014

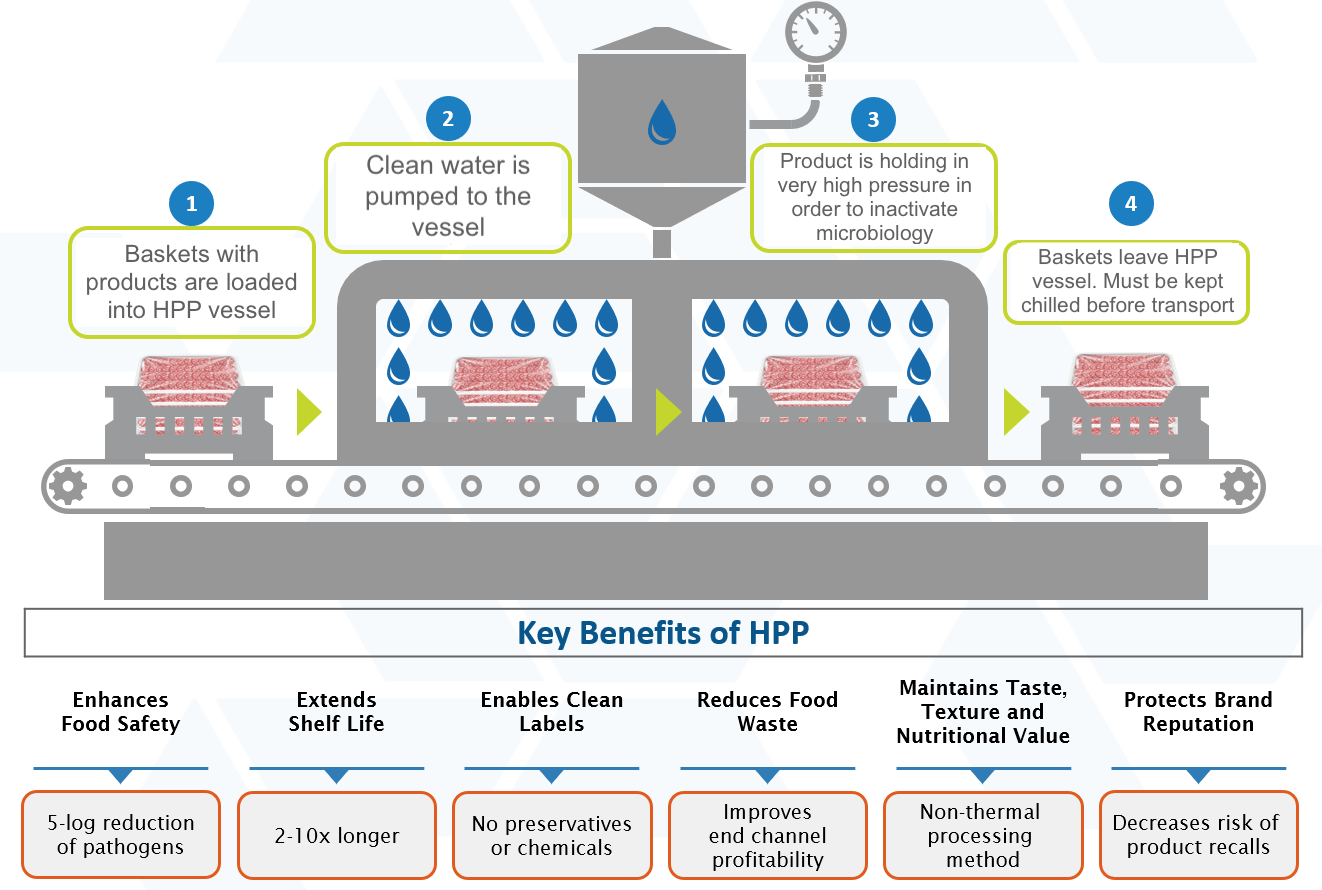

PROCES (HPP TECHNOLOGY)

The HPP process is performed in special pressure equipment (Fig. below) called hpp systems, manufactured in accordance with pressure standards and designed in a compliant with food safety standards HACCP. HPP systems are fully automated and adapted to continuous multi-shift operation. The whole process involves manual loading into a special baskets with packaged products (1). The packaging must be flexible and tight. The cycle is then fully automatic – of course, loading the baskets can also be automated. The product baskets enter the pressure vessel (2) with the help of conveyors, where product is pressurized up to 6000 bars (3), after which the vessel is decompressed and after minute(s) the baskets leave the vessel (4) so that new baskets can be loaded. New and loaded baskets always waiting in front of vessel.

High-pressure process in 4 steps (scheme)

- Loading the product into a pressure vessel.

- Pre-filling. Pressure boost up to 6000 bar

- Hold in certain amount of time and pressure decompression

- Water emptying (closed system. Unloading of tank and hoppers –> cycle is repeated

read more about HPP here

read more about HPP Technology here

read more about HPP Advantages here

read more about HPP Applications here